Specialty Manufacturing

At MMT, we can ensure your product is manufactured at the highest quality with automation efficiencies, whether your product is in the initial R&D development stages or at full-scale production.

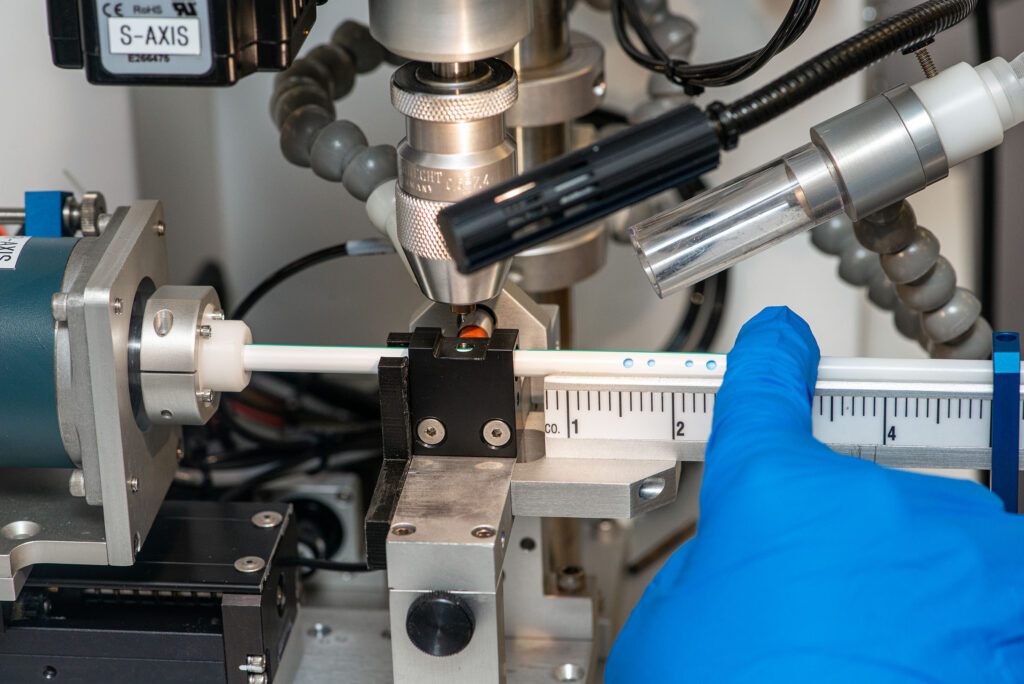

Our facility in St. George, Utah is home to ISO 14644-1 Class 7 Cleanroom where we focus on tipping, bonding, flaring, and hole drilling your catheters and medical components with quality and precision.

We are proud to utilize in-house production equipment and tooling to perform manufacturing functions to support our customers.

Drawing on designs from our standard automation solution platform, our medical device specialty manufacturing service division can process various medical-grade materials, including single-lumen or multi-lumen tubing, wire-reinforced tubing, and nitinol wire. At MMT, you have access to custom short and long-run catheter manufacturing services and medical tubing assembly services, including:

- Cut-to-length services

- Hole-making

- Tube slitting

- Tip forming and flaring

- Printing

- Laser-marking

*Not all sites are ISO certified.

Automation

MMT specializes in the design, development, and production of customizable automated and semi-automated systems with the purpose of improving quality and supporting operators and technicians in manual and resource-heavy operations.

Catheter Component Processing

MMT provides catheter component and guidewire component manufacturing services to various OEMs and other contract manufacturers.

Device Assembly Services

MMT offers catheter component processing and assembly. Gain a competitive advantage with MMT as your committed manufacturing partner.