Catheter Component Processing

MMT provides catheter component manufacturing services to various OEMs and other contract manufacturers. Its services support varying volumes along the device life cycle, from R&D, and low-volume device manufacturing situations to high-volume, outsourced component, and assembly situations.

Component services are available a la cart or in a multi-operation, turn-key fashion! Request more information today!

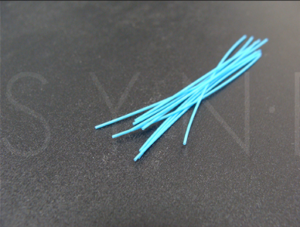

Cut to Length Services

Square and burr-free cut ends and precision lengths are critical for minimizing tolerance stack ups or reducing the risk of butt weld failure. For medical device manufacturers, we use the custom-designed SYNEO machines to create a competitive advantage for our catheter assembly customers.

We maintain a robust line of SYNO Accu-Cut machines to handle a wide range of tubing and catheter shaft applications. SYNEO Accu-Cut 202L, Accu-Cut700L, and Accu-Cut CTXL tube cutting machines and quick-turn tooling resources are available to cut a wide range of braided and non-braided shafts and materials.

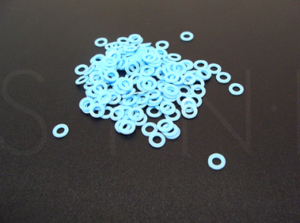

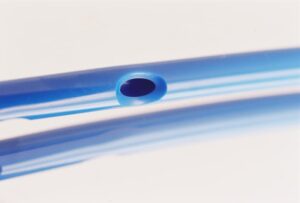

Hole Punching, Drilling and Cutting Services

Precise, burr free holes in catheter bodies are critical to catheter device performance and patient well-being.

MMT utilizes both manual and automated equipment under the Cathtip and SYNEO brands to process a wide range of catheter-hole drilling and punching applications.

The equipment line includes the Cathtip Flex-Drill and 400 Series, as well as the SYNEO manual and automated Accu-Drill machines.

Our dedicated applications personnel, equipment, and tooling offering provide robust solutions for round, oval, odd-form, and off-center skive hole punching applications.

Leverage the robust line of hole-drilling applications and cutting tools available under the MMT portfolio, today.

Catheter Tip Forming & Bonding Services

Flash and burr free catheter tips are essential to an atraumatic device introduction and delivery. MMT offers a robust line of catheter tipping solutions, including Radio Frequency Tipping (RFT) and glass die tipping.

MMT offers precision tipping and bonding of polyurethanes, nylons, and other thermoplastic materials required to fabricate catheters and other minimally invasive medical devices. Our quick-turn, in-house machine shops can provide any tip-forming tooling necessary for any specialty tip shape needed.

Request a quote today!

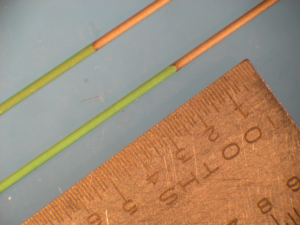

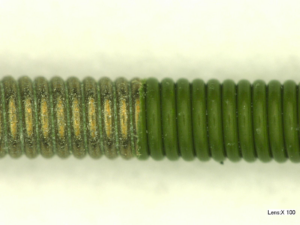

Identification & Surface Attribute Services

Surface modification through laser marking or sandblasting can be an excellent alternative to traditional depth mark printing on catheters or guidewires. These same surface modification processes can also be leveraged for increased adhesion with glued or insert molded components.

Through internal equipment and external partnerships, MMT offers laser marking (laser etching) services, printing services, and micro-blasting services for surface removal, serialization, and marker band applications.

Need tubing selection or extrusion support?

MMT maintains partnerships with extrusion houses specializing in medical-grade extrusions, including silicone, PTFE, and Pebax®.

Let an MMT sales manager connect you with our go-to extrusion partners to get you on the path to success!