Designing Tomorrow’s Production Floor Today.

1

1

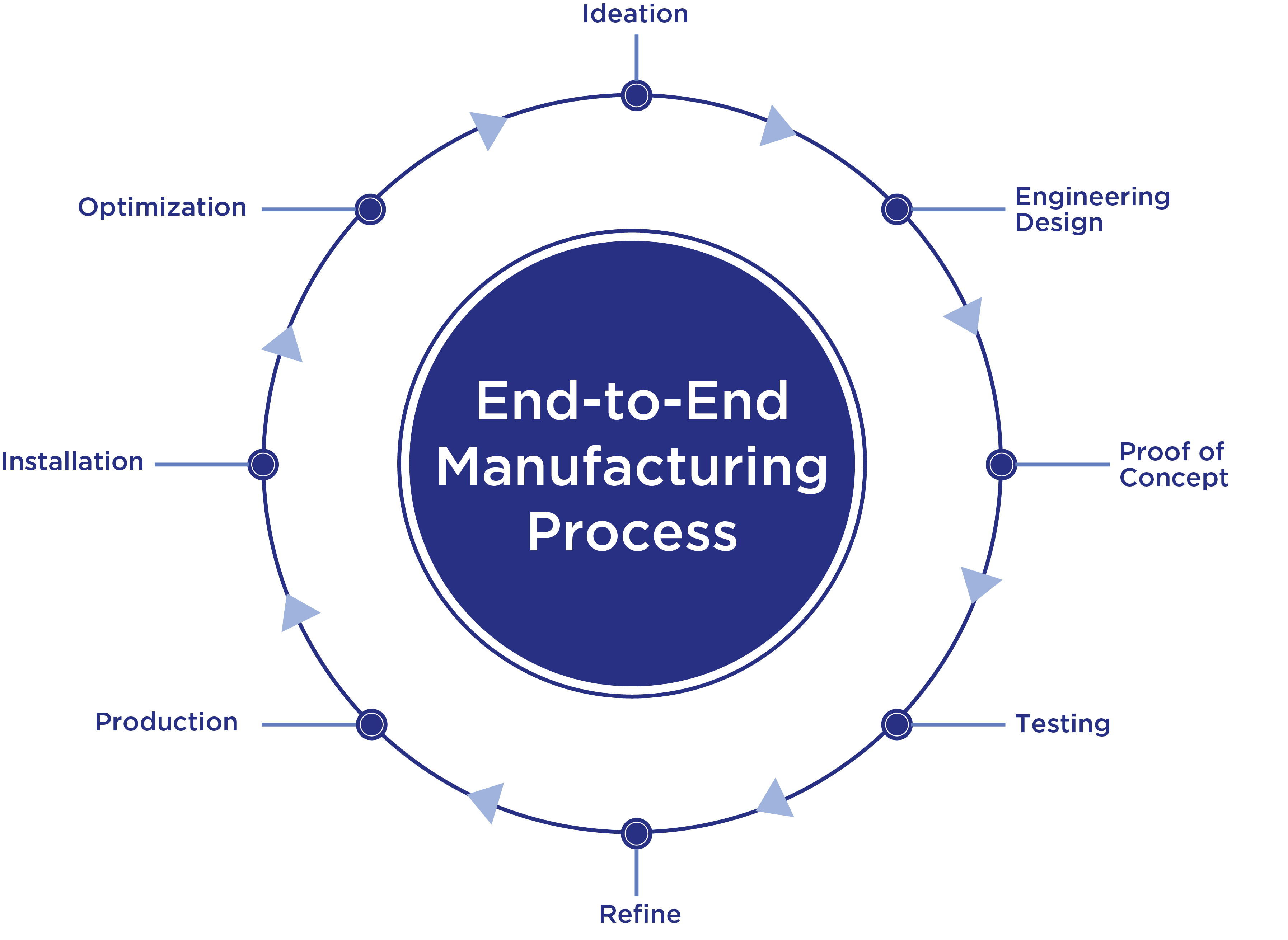

Now that you have conceptualized a process or device to solve a problem or enhance a current solution our team of skilled engineers are here to help you make it a reality.

Our team of highly skilled engineers will apply their expertise to conceptualize, design, and develop a solution that aligns with your exact specifications.

Our team of skilled engineering professionals specializes in creating reliable proof-of-concepts and prototypes, which are crucial for showcasing the feasibility and benefits of your product, process, or solution.

In order to ensure high-quality results, it is important to test your product or process in real-world conditions to identify and mitigate potential risks.

Our team understands that it may be necessary to refine a process to ensure quality standards and output are met.

Our experienced team of engineers work closely with you to ensure that your equipment solutions & processes are optimized and meet all regulations and standards.

We are dedicated to providing you with comprehensive installation services and support to ensure that your equipment solution is optimized to your exacting requirements on day one.

At MMT, we work tirelessly to optimize your product and processes, keeping you competitive now and in the years to come.

Our automation experts work with customers to develop world class robotic systems and integration solutions for their unique operations. Our solutions are proven to create cost-saving efficiencies, deliver exceptional quality, achieve faster time to market, streamlined operations and increased profitability.

CASE STUDY | VisionPick

Somex Automation have developed The “VisionPick” standard platform for providing Machine Vision Guiding of Pick & Place equipment. The technique can be used for picking components from loose, bulk condition so that the component is individually precisely located for the subsequent placement into a process or location. The application can be used for assembly processes, packaging processes and automated inspection. This technique is far superior to conventional techniques such as vibratory bowl feeding as it is more gentle on the component, less noisy, less particulate generation & more flexible.