Precision Catheter Hole Forming Equipment

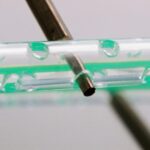

Single & multi-lumen tubing applications require precise, flash-free holes, plug collection, lumen location and detection, and 360 degree hole pattern capabilities. SYNEO’s hole-making equipment and tooling are the standard industry solution.

Enhanced features such as multi-lumen (or specific-chamber) location, hole visual inspection and plug collection enhance quality outcomes and efficiency for operators in both research & development and medical device production environments. SYNEO’s multi-lumen location feature allows operators to target specific hole patterns for individual lumens, allowing advanced configurations for skiving, punching and drilling while reducing risk of cross-communication between other lumens (tubing chambers).

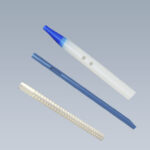

SYNEO’s manual hole punching machines are ideal for R&D, point-of-use and low volume production capacities, while SYNEO’s automated line of programmable catheter hole drilling machines increases the feasibility of high-volume throughput while maintaining product integrity and quality standards for the most demanding catheter punching and drilling applications.

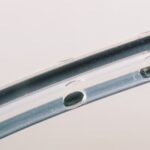

SYNEO Accu-Drill and Accu-Punch products are medical tubing punching and hole drilling machines that utilize cutting and coring tools featuring SYNEO’s proprietary hollow core sharpening technology to create flash-free, burr-free holes in tubing applications as small as .005”.

SYNEO offers a variety of manual and automated equipment solutions that utilize SYNEO cutting tools. SYNEO manufactures precision cutting tools with unparalleled sharpness for drilling, punching, and skiving holes in catheter tubing and tissue-cutting medical devices. Featuring SYNEO’s proprietary Hollow Core Sharpening Technology, SYNEO’s medical precision cutter punches are manufactured to the tightest of specifications in a wide array of round, oval and odd-form coring blade or punch styles to create flash-free, burr-free holes in tubing and tissue applications as small as .005″.